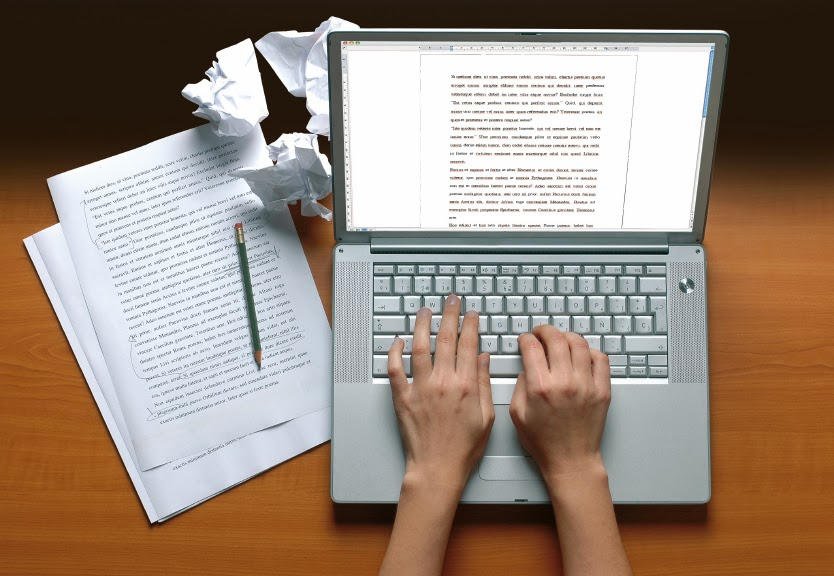

In the rapidly evolving world of electronics, sourcing the right components is critical to the success of any project, whether it’s for consumer electronics, industrial machinery, or cutting-edge technology development. Electronic components buyers play a crucial role in ensuring the supply chain runs smoothly and that manufacturers receive the high-quality parts they need to keep production on track. However, navigating the complexities of this role can be challenging, and even seasoned buyers can make costly mistakes.

Here, we outline the top 5 mistakes electronic components buyers should avoid to ensure smooth and efficient procurement processes.

1. Failing to Verify Supplier Credibility

One of the biggest mistakes electronic components buyers make is neglecting to thoroughly verify the credibility of suppliers. With an increasing number of suppliers, particularly from global markets, there’s always a risk of encountering counterfeit or substandard components. Buyers who rush into deals without performing due diligence may end up with products that don’t meet specifications or, worse, are completely unusable.

To avoid this, always take time to research and verify your supplier’s credentials. Look for certified and reputable suppliers, check customer reviews, and make sure the supplier adheres to industry standards such as ISO 9001 for quality management. You can also ask for references from other clients or request documentation proving the authenticity and quality of their products. Additionally, working with an authorized distributor can help you avoid counterfeit parts, providing peace of mind regarding the components’ origin.

2. Not Keeping Track of Market Trends and Pricing Fluctuations

In the electronic components industry, prices can fluctuate rapidly due to market conditions, supply chain disruptions, or changes in demand. One mistake that electronic components buyers often make is failing to stay updated on market trends and pricing shifts. This can result in overpaying for components or being unprepared when prices spike due to shortages or unexpected events.

To avoid this, electronic components buyers should closely monitor market trends and anticipate potential price changes. This can be done by subscribing to industry reports, working with suppliers who provide market intelligence, and building relationships with reliable partners who can alert you to upcoming price hikes or shortages. Staying informed can also help you plan your purchases strategically, locking in favorable pricing during times of price stability or downturns.

3. Ignoring Lead Time and Inventory Planning

Lead times can vary significantly between suppliers and components, and failing to account for these differences can lead to production delays, missed deadlines, and increased costs. A common mistake electronic components buyers make is underestimating how long it will take to source certain parts, especially during times of high demand or supply chain disruptions.

To avoid this, it’s essential to have accurate lead time data for all the components you need and plan your purchases accordingly. Buyers should also communicate regularly with suppliers to get real-time updates on availability and potential delays. Additionally, keeping a well-managed inventory buffer for critical components can help mitigate the impact of supply chain disruptions or unexpected delays in procurement.

4. Overlooking Quality Control Processes

Quality control is a crucial aspect of the procurement process, and overlooking it can lead to severe consequences, such as product failures, recalls, or reputational damage. Some electronic components buyers make the mistake of assuming that if a component looks good on paper, it will perform well in practice. However, components need to be thoroughly tested and validated to ensure they meet performance standards and are free of defects.

Buyers should always have a stringent quality control process in place, either through their suppliers or their internal teams. This includes conducting batch testing, requesting quality certifications, and ensuring that components pass rigorous inspections before they are used in production. Working closely with suppliers who adhere to international quality standards and have robust testing protocols will help minimize the risk of receiving faulty components.

5. Neglecting Long-Term Supplier Relationships

Focusing solely on short-term gains, such as securing the lowest possible price, is another mistake electronic components buyers often make. While cost-saving is essential, neglecting to build long-term relationships with suppliers can hurt your procurement efforts in the long run. Having a strong partnership with suppliers can provide numerous benefits, such as priority access to scarce components, better pricing negotiations, and more reliable service during times of crisis.

To avoid this, electronic components buyers should prioritize building and maintaining long-term supplier relationships based on trust, transparency, and mutual respect. These relationships can help you navigate challenges like supply chain disruptions, sudden price hikes, or quality issues more effectively. In the long term, strong partnerships with key suppliers will make your procurement process more resilient and reliable.

Conclusion

Sourcing electronic components is a complex task that requires careful planning, attention to detail, and a deep understanding of the market. By avoiding these top 5 common mistakes—failing to verify supplier credibility, not keeping track of market trends, ignoring lead times, overlooking quality control, and neglecting long-term supplier relationships—electronic components buyers can improve their procurement strategies, reduce risks, and ensure the smooth operation of their supply chains. With careful planning and proactive management, buyers can achieve a more efficient and reliable procurement process, setting themselves up for success in the competitive world of electronics manufacturing.