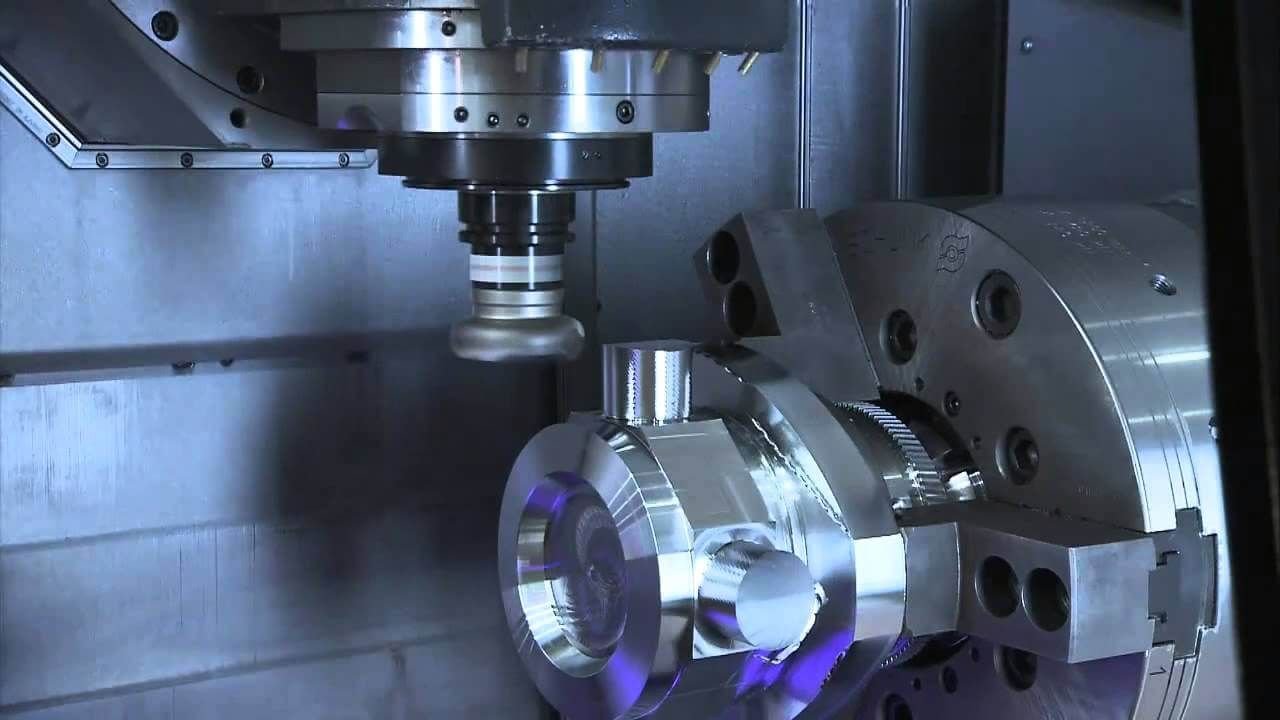

Innovations in Precision by CNC Machining Company in USA

CNC machining company in USA has become an integral part of modern industrial processes, particularly in sectors like aerospace, automotive, medical devices, and electronics, where even the slightest deviation in components can lead to major setbacks or failures. CNC machining companies are leading the way in revolutionizing precision manufacturing. By constantly improving their technology and processes, these companies are responding to the increasing demand for more accurate, reliable, and efficient production methods. Their innovations, driven by cutting-edge technologies such as automation, robotics, and artificial intelligence, are setting new benchmarks for the industry.

CNC Machining Company in USA

Precision Manufacturing’s Use of CNC Machining

CNC machining, or Computer Numerical Control machining, involves the use of computerized controls to operate tools and machinery in the manufacturing process. Unlike manual machining, CNC machining delivers far greater accuracy, allowing companies to achieve exact specifications with exceptional consistency. This level of precision is essential in industries like aerospace, where minute imperfections in a part can lead to significant malfunctions, and in medical devices, where every component must meet strict safety standards.

In the USA, CNC machining company in USA are known for their expertise in delivering precision parts for industries where quality and reliability are critical. The ability to produce components with tight tolerances, complex geometries, and intricate details has made CNC machining indispensable for a wide range of applications, from producing jet engine components to creating medical implants. As the demand for precise manufacturing continues to grow, these companies are continually enhancing their capabilities to remain at the forefront of industrial innovation.

Advancements in CNC Machine Technology

One of the key drivers of innovation in the CNC machining sector is the rapid advancement in machine technology. Multi-axis CNC machines, for instance, have revolutionized the industry. These machines can operate along multiple planes and axes simultaneously, allowing for the creation of more intricate parts in a single setup. In contrast to traditional 3-axis machines, multi-axis machines reduce the need for multiple configurations and enable faster production with fewer errors.

Moreover, the integration of artificial intelligence (AI) and machine learning into CNC machines has allowed manufacturers to further enhance precision. AI-powered algorithms can now optimize machining paths, adjust cutting parameters in real-time, and even predict tool wear and tear, preventing defects before they occur. This level of automation not only boosts the efficiency of CNC machining but also ensures higher levels of accuracy, as machines can adjust themselves based on real-time data.

The ability to control these variables with precision means that CNC machining company in USA can produce parts with extremely tight tolerances, superior surface finishes, and minimal material waste. This is particularly important in industries where quality and accuracy directly impact the performance and safety of the final product.

Automation and Robotics in CNC Machining

Automation has become a vital aspect of modern CNC machining operations. The integration of robotics into the CNC machining process has dramatically increased efficiency, productivity, and consistency. Robotic systems are often used to automate repetitive tasks like loading and unloading materials, monitoring machine operations, and even performing quality control inspections. These advancements not only increase throughput but also reduce the risk of human error, which can lead to costly mistakes in high-precision manufacturing environments.

In some CNC machining companies, robotic systems are coupled with automated CNC machines to create “lights-out” manufacturing facilities, which can operate 24/7 with minimal human intervention. This approach significantly boosts productivity, as machines continue working through the night without downtime. For industries that require large volumes of precision parts, this continuous operation is a game-changer in terms of meeting production deadlines and maintaining cost efficiency.

Robotics and automation also improve safety in CNC machining environments. By automating dangerous tasks and reducing the need for manual labor, companies can minimize workplace accidents and injuries. This is particularly important in industries like metalworking and aerospace, where the materials being handled are often heavy, sharp, or otherwise hazardous.

CNC Machining and Sustainability

As industries worldwide shift towards more sustainable practices, CNC machining company in USA are adopting greener technologies and processes to reduce their environmental impact. Sustainability in CNC machining is driven by a combination of energy efficiency, waste reduction, and the use of eco-friendly materials and lubricants.

One of the ways CNC machining companies contribute to sustainability is by optimizing material usage. Techniques like near-net-shape manufacturing allow companies to produce components that are as close to the final shape as possible, thereby reducing material waste. By starting with a shape that closely resembles the final part, CNC machines can minimize the amount of material that needs to be cut away. This not only lowers costs but also reduces the environmental footprint of the manufacturing process.

CNC Machining Company in USA

Additionally, CNC machines are now being designed with energy efficiency in mind. Many modern CNC machines use variable-speed motors, regenerative braking systems, and energy-efficient cooling mechanisms to reduce power consumption. These advancements not only help companies lower their operating costs but also contribute to their overall sustainability goals.Another growing trend is the use of eco-friendly lubricants and coolants in CNC machining. Traditional coolants can be harmful to both workers and the environment, but many CNC machining companies are now switching to biodegradable and non-toxic alternatives. These changes, along with other sustainable practices, ensure that precision manufacturing can meet the needs of today without compromising the well-being of future generations.

Conclusion:

CNC machining company in USA are at the forefront of precision manufacturing, driving innovation and setting new standards for accuracy and efficiency. Through the adoption of multi-axis machines, AI-driven processes, robotics, and sustainable practices, they are revolutionizing the way components are manufactured for critical industries. As the demand for precision continues to grow, CNC machining will remain an essential tool for delivering high-quality, reliable parts that meet the ever-evolving needs of the industrial sector.

FAQs:

Q1: What is CNC machining, and why is it important for precision manufacturing?

CNC machining is a computer-controlled process that allows for the precise production of parts with intricate designs and tight tolerances. It is essential for industries that require high accuracy and consistency in their components, such as aerospace and medical devices.

Q2: How have advancements in CNC technology improved precision?

The introduction of multi-axis CNC machines and AI-powered algorithms has

significantly improved the precision of CNC machining, allowing for more complex parts and reduced errors in production.

Q3: How does automation benefit CNC machining company in USA?

Automation, including the use of robotics, increases production speed, reduces human error, and enables continuous operation, making CNC machining more efficient and cost-effective.

Q4: How do CNC machining companies contribute to sustainability?

CNC machining companies are adopting sustainable practices by optimizing material usage, using energy-efficient machinery, and utilizing eco-friendly lubricants and coolants to minimize their environmental impact.

Q5: Why is precision manufacturing crucial in industries like aerospace and medical devices?

Precision manufacturing ensures that components meet strict specifications, which is vital in industries where even small deviations can affect performance, safety, or compliance with regulatory standards.